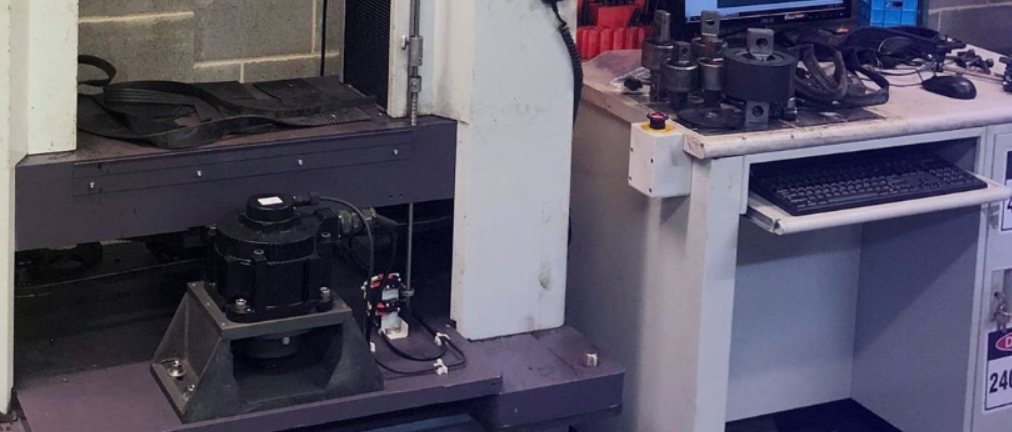

Understanding Universal Testing Machines

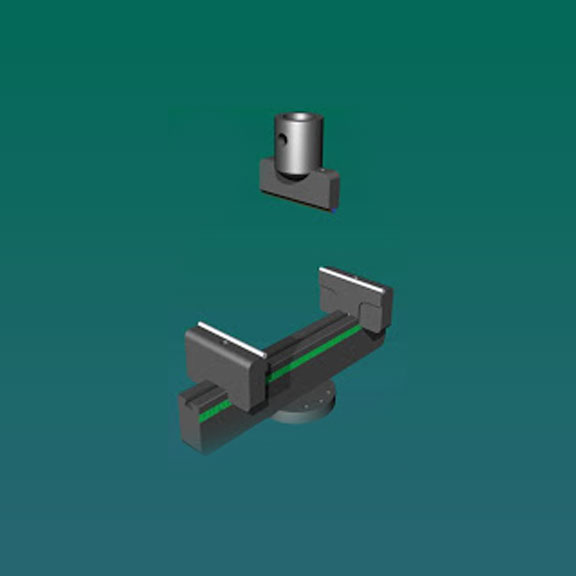

At its core, a UTM is a versatile beast in the testing world, capable of assessing various mechanical properties of materials. Whether it’s pulling, compressing, bending, or stretching, this machine tackles it all. Its ability to adapt to different tests makes it an invaluable asset in quality assurance. Imagine it as a gym for materials, where every stress test pushes the limits of strength and endurance.

The Power of Precision

Accuracy is non-negotiable in quality control. Universal Testing Machines deliver this by providing precise measurements of tensile strength, compression, and more. This precision helps in making informed decisions about material quality and suitability for specific applications. Think of it as having an eagle-eyed inspector who misses nothing, ensuring that every product is up to par.

Enhancing Product Reliability

A key benefit of using UTMs is the significant enhancement of product reliability. By identifying material defects before they become part of the final product, UTMs save manufacturers from potential failures and costly recalls. It’s like catching a typo in an important email before it’s sent—a small step that prevents bigger issues down the line.

Consistency Across Batches

UTMs ensure consistency, verifying that every batch of products meets the same rigorous standards. For manufacturers, this consistency is crucial for maintaining trust with customers. It’s similar to baking a perfect batch of cookies every time—satisfying and dependable.

Reducing Costs and Waste

Incorporating UTMs in quality control along with other efficient solutions like melt flow index machines also leads to significant cost savings. By detecting defects early, these machines reduce waste and minimise the need for reworks or scrap. Think of it as being frugal yet efficient—spending a bit more on good-quality flour to save on burnt cookies later.

Streamlining Production Processes

Streamlining production processes is another feather in the cap for UTMs. They provide data that helps optimise manufacturing techniques, improving not only product quality but also the efficiency of the production line. It’s akin to finding the best route home—saving time, effort, and fuel.

Compliance with International Standards

Adhering to international standards is no small feat. UTMs are crucial in this arena, helping manufacturers meet rigorous regulatory requirements. Whether it’s ISO, ASTM, or any other standard, these machines are the gatekeepers that ensure compliance. They’re like the diplomatic passports of the manufacturing world—opening doors and crossing borders seamlessly.

Boosting Consumer Confidence

When products are consistently reliable and high-quality, consumer confidence soars. This trust is a currency in the business world, and UTMs help in accumulating it by ensuring that products perform as advertised. It’s the secret sauce to brand loyalty, much like a grandmother’s recipe passed down through generations—time-tested and beloved.

Integrating with Modern Technologies

The integration of UTMs with modern technologies like AI and IoT elevates their capabilities. This synergy allows for real-time data analysis and enhanced predictive maintenance, ensuring the machines are always at peak performance. It’s like having a smart home system that adjusts the temperature just right—always comfortable, never too hot or cold.

The Role of Data in Innovation

Data collected from UTMs can lead to groundbreaking innovations in material science. By understanding material limits and behaviours under different stresses, researchers can develop new materials that revolutionise industries. This is the bedrock for innovations that could one day make our cars lighter, our bridges stronger, and our smartphones more durable.