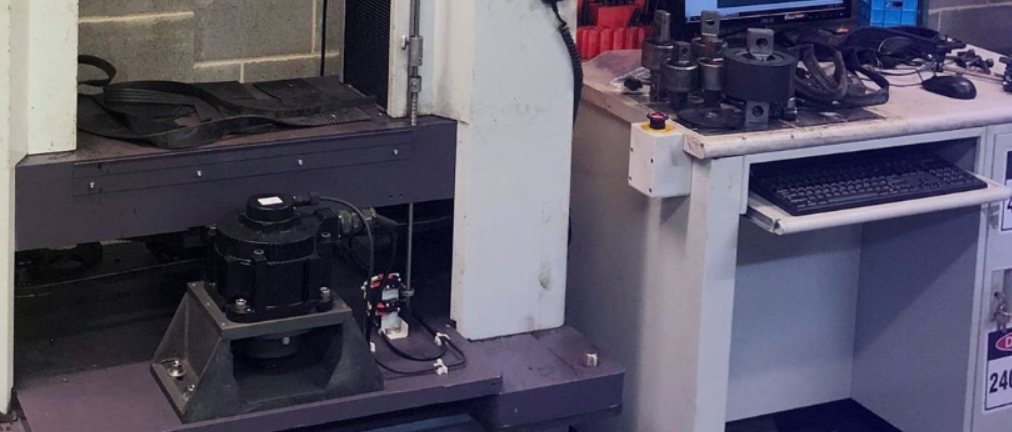

Understanding Universal Testing Machines

A Universal Testing Machine, as the name suggests, is a versatile piece of equipment used to evaluate the mechanical properties of materials. They measure tensile strength, compression, and elongation—key factors that determine a material’s capability to withstand forces.

- Tensile Strength: A UTM stretches a material to determine how much pulling force it can endure before breaking. It’s like tug-of-war but with metal, plastic, or any material under scrutiny.

- Compression: Imagine squashing a marshmallow between your fingers, but instead of marshmallow, think of steel or concrete. UTMs measure how much a material can compress before it crumbles.

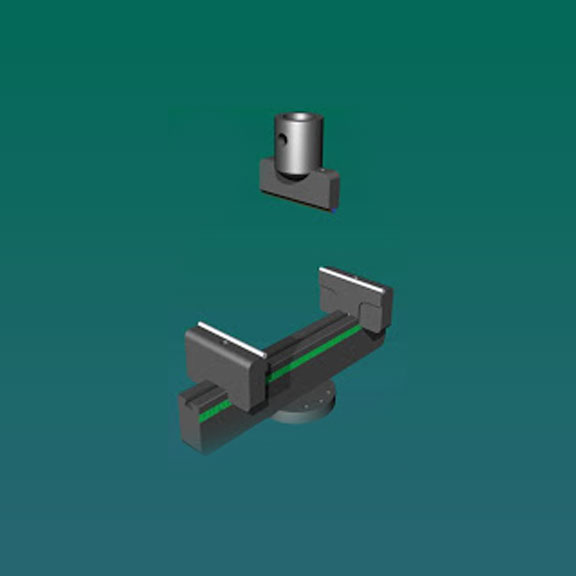

The Role of Charpy Impact Testers

While UTMs focus on gradual stress, a Charpy Impact Tester is all about sudden force. They measure a material’s toughness, which is its ability to absorb energy during impact. Picture a hammer swinging down on a material. The Charpy Impact Tester records how much energy is absorbed before the material fractures.

- Impact Energy: The core of this test is the amount of energy the material absorbs before it snaps. This information is crucial for applications where sudden impacts are a risk, like in automotive crashes.

- Fracture Behaviour: How does a material break? Does it shatter like glass or bend before snapping? The Charpy Impact Test provides answers, ensuring that materials behave predictably under impact.

In industries where safety is paramount, like in vehicle manufacturing or construction, knowing how a material will react in a collision can be the difference between life and death.

Why Material Testing Matters

You might be wondering why all this testing is necessary. Can’t we just trust that materials are strong enough? The answer is a resounding no. Here’s why:

- Safety: Whether it’s the steel beams holding up a skyscraper or the components in your car’s airbag system, knowing how materials behave under stress is critical. UTMs and Charpy Impact Testers make sure that only materials that meet the highest standards are used.

- Reliability: Engineers need data they can rely on. Material testing provides the hard facts—literally—about what a material can handle. This leads to better designs and safer products.

- Cost-Efficiency: By understanding a material’s limits, companies can avoid costly failures. There’s nothing worse than a product recall because a material didn’t perform as expected.

Real-World Applications

Material testing isn’t just for show; it’s used in practical, real-world applications every day:

- Construction: The beams, bolts, and concrete used in building skyscrapers all go through rigorous testing to make sure they can handle the weight and environmental factors.

- Automotive Industry: Crashworthiness depends on materials that won’t shatter on impact. Cars are tested, but so are the materials that make them.

- Aerospace: Planes fly through some of the harshest conditions. Every material on board is tested to make sure it can handle extreme temperatures and pressures.