Understanding Strain Gauges: A Tiny Titan of Tension

What is a Strain Gauge?

A strain gauge consists of an electrical conductor arranged in a fine grid pattern. When an object stretches or compresses, the strain gauge deforms, causing its electrical resistance to change. This change in resistance is proportional to the strain experienced by the gauge, offering a precise measurement of stress and strain dynamics.

Types of Strain Gauges and Their Applications

Strain gauges come in various types, each tailored to different applications. For instance, foil strain gauges, made of a thin metal foil patterned between two thin sheets of insulation, are widely used due to their accuracy and low cost. Semiconductor strain gauges, though more expensive, provide a higher degree of sensitivity and are used in situations requiring meticulous measurements, such as in aerospace engineering and biotechnology.

The Critical Role in Engineering

Ensuring Structural Integrity

One of the paramount applications of strain gauges is in civil engineering, where they play a crucial role in monitoring the structural health of buildings and bridges. By providing real-time data on the stress levels these structures endure daily, engineers can predict potential failure points and prevent catastrophic collapses.

Revolutionising Material Science

Strain gauges are also instrumental in material science, aiding researchers in understanding the properties of different materials. Through meticulous testing, scientists can determine how materials will behave under various conditions, leading to innovations in materials used in everything from everyday household products to advanced aerospace components.

Strain Gauges in Action: Real-World Applications

Aerospace: High Stakes and High Stress

In the high-stakes world of aerospace, strain gauges are used to test everything from the wings of an aircraft to the fuselage. Engineers rely on these tools to ensure that every component can withstand extreme conditions, thus safeguarding the lives of millions of passengers.

Automotive Industry: Driving Safety Forward

Similarly, in the automotive industry, strain gauges are essential for crash tests. They help engineers understand how various forces impact a vehicle during a collision, leading to the design of safer vehicles that can better protect occupants in the event of an accident.

Technical Insights: How Strain Gauges Contribute to Precision

Calibration and Accuracy

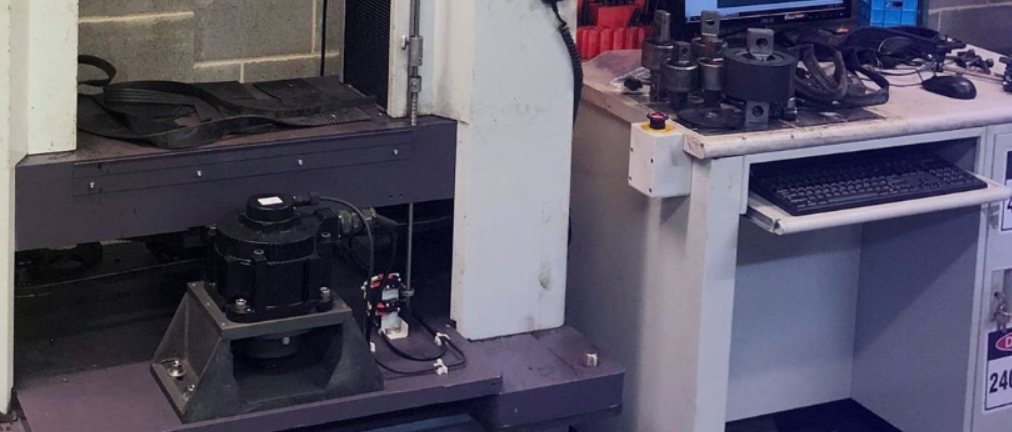

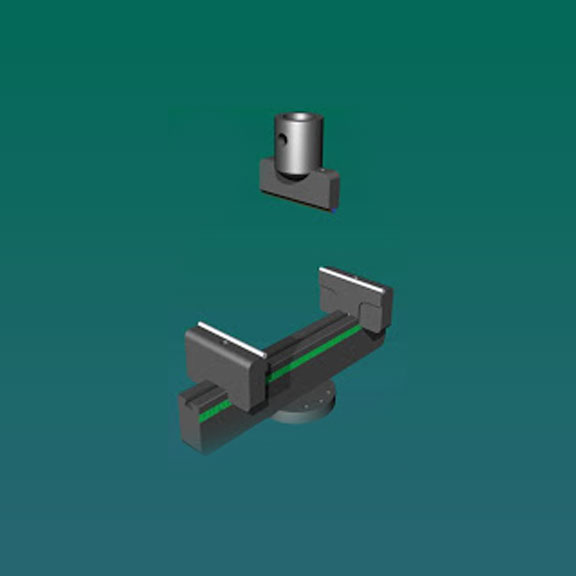

In any scientific experiment or industrial application, accuracy is paramount. This is where strain gauges shine, especially in tasks like UTM calibration. Universal Testing Machines (UTMs) rely on strain gauges to ensure their pressure sensors are producing accurate readings, which is crucial for maintaining the integrity of mechanical testing.

The Electronics Behind the Measurements

The operation of strain gauges involves complex electronic components that convert mechanical motion into readable electronic data. Engineers use these readings to make informed decisions about material properties and structural changes, ensuring that all calculations are grounded in solid, empirical data.

The Future: Strain Gauges in Innovative Fields

Pioneering New Technologies

As we push the boundaries of technology, strain gauges are finding their place in the development of smart materials and nanotechnology. These fields demand an incredibly high level of precision and reliability, areas where strain gauges excel.

Material Testing and Beyond

The adaptability of strain gauges means they are not just limited to traditional engineering fields. Innovative applications are emerging in areas such as medical devices, where strain gauges are used to create more effective prosthetics that respond better to the human body’s natural movements.